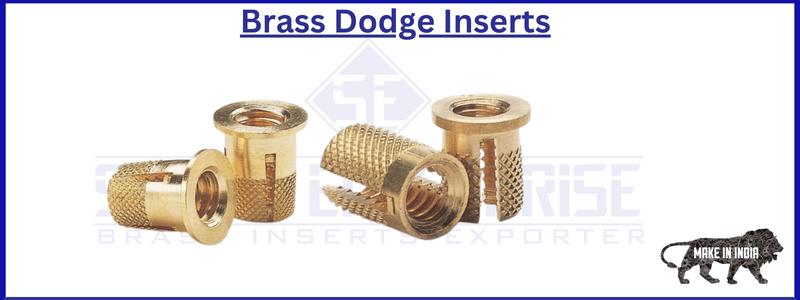

Brass Dodge Inserts

Brass Dodge Inserts items called Dodge® threaded inserts for plastics are made to give sturdy metal threads in plastic components. They are offered in a variety of knurl and undercut styles to accommodate practically any plastic threaded assembly application.

Dodge® inserts can be fitted in a number of techniques, such as self-threading, hot or cold pressing, mold-in, and ultrasonic welding. Examples of typical applications include those in the automotive, communication, aerospace, defense, and medical sectors..

Brass Dodge Inserts Installation

Brass Dodge Inserts is put in victimization inaudible instrumentation (moderate to high production) or thermal installation instrumentation (prototype work and low amount production). Thermal instrumentation is as easy as a hand tool command by hand or mounted in associate arbor or drill press. a lot of refined instrumentation is obtainable with changes and settings for precise, uniform installations.

|

|

|

|

Quality of Dodge Inserts

Brass Dodge Inserts products are manufactured to the same exacting quality systems required by the military, aerospace, and automotive standards. The Danbury manufacturing facility has been certified ISO/TS 16949: 2009 and ISO 14001. We are committed to an ongoing and never-ending process of quality improvement and total customer satisfaction.

Threaded Inserts

Brass Dodge Inserts are designed to provide the high-performance strength values of molded-in inserts while retaining all of the economical advantages of insert installation after molding.

Compression Limiters

Brass Dodge Inserts non-threaded bushings expand the Dodge offering and are custom designed for your specific application. The Limiters can be pressed in or installed with either heat or ultrasonic. They are designed to minimize any cracking of plastic parts due to bolt load.

| Standard: | DIN,ASTM/ANSI JIS EN ISO,AS,GB | ||||||

| Material | Stainless Steel: SS201, SS303, SS304, SS316,SS316L,SS904L ,F594 | ||||||

| Steel Grade: DIN: Gr.4,5,6,8.8,10,; SAE: Gr.2,5,8; ASTM: A563 | |||||||

| Finishing | Zinc(Yellow,White,Blue,Black),Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated |

||||||

| Production Process |

M2-M24:Cold Froging,M24-M100 Hot Forging, Machining and CNC for Customized fastener |

||||||

| Customized Products Lead time |

Busy season:15-30days,Slack seaon:10-15days | ||||||

| Stock Products | Carbon steel:DIN934,DIN6923,DIN928,DIN929,ISO4032,Cage nut,Cap nut,etc Stainless steel: All DIN Or GB Standard stainless steel Nut |

||||||

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.

We can manufacture and export Brass Products as per specifications (custom drawing and samples) for more information, please