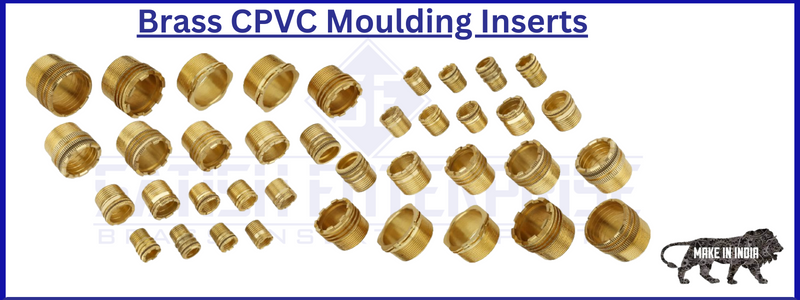

Brass CPVC Moulding Inserts

We are among the main manufacturer, supplier and exporter, occupied with offering a restrictive scope of Brass CPVC Moulding Inserts to our customers in differed sizes.

we are Offered items are made utilizing high-review quality crude material, as per the mechanical standards and rules. These fittings are acknowledged generally for their resistance against erosion and scraped area, dimensional exactness and great quality. We are a main producer of Brass additions for CPVC Fittings. Our Product suits for all sorts of injection molding and Plastic Molding Industries.

We always manufacture and design Brass Inserts as per the custom needs of our clients. Brass Inserts are available in different sizes and specifications to fulfill the industry’s needs.

We are a reputed Brass Inserts Manufacturer for CPVC Pipe Industries. We don’t make any compromise on quality standards.

Just send us your drawing or sample details, So our professional engineers will choose the best manufacturing solution for your Brass Inserts Requirements.

Specification Brass Moulding Inserts

Knurling Available:

- Diamond

- Straight

- Unidirectional

- Both blind and through inserts are available

Material of Inserts:

- Free Cutting Brass IS 319

- Free Cutting Brass as per BS 249

- High Grade Free Cutting Brass or

- Any special Brass Material Composition as per customers requirement

Threads of Moulding Inserts:

- ISO metric (MM Threads)

- BA Threads

- BSW Threads

- UNC & UNF Threads

- As Per Customers Requirement

Key Features of Product:

- In such cases the length of insert is very important for proper closing of moulding die. We maintain length of such inserts within tolerance of -0.05mm.

- Thread Size Starts from M16 to M50, BA, BSW, BSPT, BSF & American Threads like UNC, UNF, UNEF, and NPT are also available as per custom requirements.

- Straight, Diamond, opposite diagonal etc. are the knurling options available to give solid gripping to Molding applications.

- Inserts available as per Class 2B ANSI/ASME B1.1 & Confirms to ISO metric 6H Thread Standards.

- Inserts with collar series provides Options to use Flange to make Electric Contact Airgrip

- series with Opposing Diagonal Knurls provide excellent Torque Resistance.

- Vertical Undercuts in Tri Series Provides superior Tensile Strength

- Blind thread or closed bottom Inserts prevents plastic from entering the bottom of the insert.

Finishing and Plating:

- Natural, Nickel Platted, Chrome Platted, Tin Plated or any coating as per customer needs and requirements.

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.

We can manufacture and export Brass Products as per specifications (custom drawing and samples) for more information, please