Brass Self Tapping Inserts

Enrich the vast experience in this field we, at Satish Enterprise, provide premium quality Brass Self Tapping Inserts as per national and international standards. We have highly skilled staff, quality control department and latest technology oriented machines and superior quality of raw material so our team members produce accurate design, finish and error-free products.

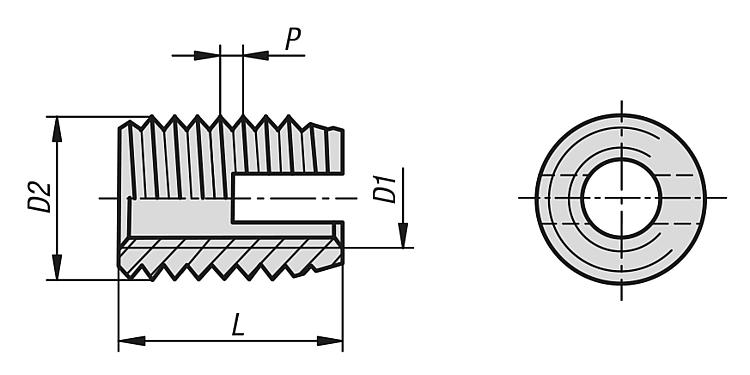

Our created Special design makes them ideal for ABS, particleboard, wood, and foamed plastics. Our inserts have internal and external thread and they are specially designed to cut their threads as they are being driven into a drilled hole. The thread cutting action is performed by the cutting slots on the insert. By tapping its thread, the self-tapping insert eliminates the need for pre-taped holes.

Large coarse outer threads give great holding power in weaker materials while inside threads stay clean, free of chips. They provide high torque and pull-out resistance. Our premium quality brass inserts are highly appreciated by our priceless customers in the global market.

|

|

|

Characteristics:

- Self-Tapping Inserts are tapered at the bottom and have a cutting slot.

- By screwing in they cut their own threads inside a receiver hole.

- Guarantees a completely secure and firm anchoring in the host material.

- The Self-Tapping inserts with cutting slot spring slightly inwards in the slot region in some materials.

- This results in a screw locking effect.

- If this is not desired, we recommend the threaded inserts with a cutting bore.

- Single Piece, Precision turned parts with both external and internal metric threads.

Advantages:

- Provide high strength, wear free, vibration resistant screw connection in materials with low shear strength such as aluminium and aluminium alloys, brass, bronze, cast iron and thermoplastics.

- Self-Tapping Threaded inserts with cutting slot are tapered at the bottom and by screwing in they cut their own threads inside a receiver hole.

- Slots provide Rapid Cutting Action.

- Friction between the insert and the plastic permanently holds it in place after installation.

- Meet RoHS Requirement and UL Listed.

Specification of Brass Self Tapping Inserts

Threads:

- ISO metric (MM Threads)

- BA Threads

- BSW Threads

- UNC & UNF Threads

- As Per Customers Requirement

Finishing and Plating: Natural, Nickel Platted, Chrome Platted, Tin Plated or any coating as per customer needs and requirements.

Brass Self Tapping Insert Application:

- Heavy machinery

- Plastic Industries

- Furniture Industry

- Electronic Industry

- Automobile Industry

- Passenger & commercial vehicles, engines, transmissions, radiators

- Marine

- Military applications – tanks, aircraft

- Plant & equipment construction

- Office machinery

- Household appliances – vacuum cleaners, cameras, sun lamps

- Instrumentation

- Telecommunications & Electrical Accessories

- Plastic Cases Assembly, etc…

Dimension specification of Self-Tapping Inserts

| Thread Size | 0C ±0.004 |

GB ±0.005 |

Role Diameter +.003-.000 |

0 ±0.005 |

Hole Depth Minimum |

0 ±0.005 |

Hole Depth l\f inimum |

|

|---|---|---|---|---|---|---|---|---|

| #2-56 UNC | 0.122 | 0.142 | 0.127 | – | – | 0.115 | 0.150 | |

| #2-56 UNC | 0.122 | 0.142 | 0.127 | 0.157 | 0.192 | – | – | |

| #4-40 UNC | 0.153 | 0.186 | 0.158 | – | – | 0.135 | 0.170 | |

| #4-40 UNC | 0.1 53 | 0.186 | 0.158 | 0.226 | 0.261 | – | – | |

| #6-32 UNC | 0.184 | 0.217 | 0.189 | – | – | 0.150 | 0.185 | |

| #6-32 UNC | 0.184 | 0.2 17 | 0.189 | 0.28 1 | 0.316 | – | – | |

| #8-32 UNC | 0.218 | 0.249 | 0.223 | – | – | 0.185 | 0.220 | |

| lf8-32 UNC | 0.219 | 0.249 | 0.223 | 0.321 | 0.356 | – | – | |

| # 10-24 UNC | 0.248 | 0.279 | 0.253 | – | – | 0.225 | 0.260 | |

| # 10-24 UNC | 0.248 | 0.279 | 0.253 | 0.375 | 0.410 | – | – | |

| #10-32 UNF | 0.248 | 0.279 | 0.253 | – | – | 0.225 | 0.260 | |

| # 10-32 UNF | 0.248 | 0.279 | 0.253 | 0.375 | 0.4 10 | – | – | |

| Y.-20 UNC | 0.311 | 0.340 | 0.316 | – | – | 0.300 | 0.335 | |

| Y.-20 UNC | 0.31 1 | 0.340 | 0.316 | 0.500 | 0.535 | – | – | |

| Y.-28 UNF | 0.311 | 0.340 | 0.316 | – | – | 0.300 | 0.335 | |

| ‘!.-28 UNF | 0.31 1 | 0.340 | 0.3 16 | 0.500 | 0.535 | – | – | |

| 3/8-16 UNC | 0.464 | 0.498 | 0.469 | – | – | 0.375 | 0.410 | |

| 3/8-16 UNC | 0.464 | 0.498 | 0.469 | 0.500 | 0.535 | – | – | |

| 3/8-24 UNF | 0.464 | 0.498 | 0.469 | – | – | 0.375 | 0.410 | |

| 3/8-24 UNF | 0.464 | 0.498 | 0.469 | 0.500 | 0.535 | – | – | |

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer of CNC parts for over 14 years.

Q2: How can I get quotation?

A2: Please help to send drawing (2D and 3D drawing) to us, so we can know the raw material, size and surface treatment, tolerance and other details of the product. And also inform us the quantity you need.

Q3: What kind of material you can process?

A3: Normally Aluminum alloy and stainless steel, but we also can do titanium alloy steel, copper alloy steel special alloy steel and non-metal material.

Q4: What is the minimum size tolerance you can do?

A4: The minimum size tolerance we can do is 0.001mm.

Q5: What is the biggest range you can do?

A5: The biggest range we can do is 1500mm.

Q6: Can you do precise and complicated CNC parts?

A6: Yes, we can do precise and complicated CNC parts by our 5/4/3 axis CNC machines

Q7: Can you accept sample order?

A7: Yes, we can do sample order per your requirement.

Q8:Can you accept custom packing?

A8: Yes, we can do custom packing as your requirement.

We can manufacture and export Brass Products as per specifications (custom drawing and samples) for more information, please